Basket

(0)

Search

Motor drives with servo motors - SMS program

Widespread use for servo technology with various types of gears.

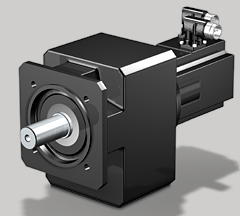

SMS LEAN GEARED MOTOR - C SERIES:

- Many type of mounting options due to the different designs of housing.

- Gear sizes from C0 to C9

- Acceleration moments from 21 to 8.000Nm

- Gear ratios from 2 to 276

- Airiness<10 to 20arcmin

- Three EK motor sizes from EK501 to EK803

- Six ED motor sizes from ED 202 to ED808

SMS FLAT DRIVES - F SERIES:

These drives are suitable for installation in tight spaces due to flat housings and large wheelbase.

- Gear sizes from F1 to F4(F6)

- Acceleration moments from 45 to 1.100Nm

- Gear ratios from 4,3 to 552

- Airiness - reduced class <5 to 8 arcmin

- Three EK motor sizes - from EK501 to EK803

- Six ED motor sizes - from ED 202 to ED808

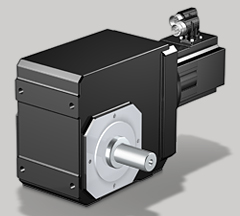

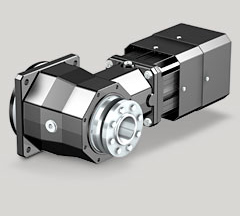

SMS ANGULAR GEAR UNIT - K SERIES:

These gear units offer a new solution in servo technology. Variety due to the angular housing in flange outlet versions, with hollow or solid axis.

- Gear sizes from K1 to K10

- Acceleration moments from 42 to 13.200Nm

- Gear ratios from 4 to 381

- Airiness - reduced class <1,5 to 3 arcmin

- Three EK motor sizes - from EK501 to EK803

- Six ED motor sizes - from ED 202 to ED808

SMS SERVO ANGULAR GEAR UNIT - KS SERIES:

New type of gear unit for the high demands of dynamic gear units or the strength of drives with continuous operation at high speeds.

- Gear sizes KS4, KS5 and KS7

- Acceleration moments from 22 to 400Nm

- Gear ratios from 6 to 140

- Airiness <4 to 6 arcmin

- Three EK motor sizes - from EK501 to EK803

- Six ED motor sizes - from ED 202 to ED808

SMS WORM REDUCER - S SERIES:

Angular drive with special favorable housing dimensions, optimal solutions for cost-effective alternatives for torques up to 800Nm.

- Gear sizes from S0 to S4

- Acceleration moments from 23 to 800Nm

- Gear ratios from 6 to 683

- Three EK motor sizes - from EK501 to EK803

- Six ED motor sizes - from ED 202 to ED808

SERVOMOTORS SERIES ED:

- Optimal motors for highly dynamic applications with minimum mass moment of inertia, slender construction.

- Brushless, electronically commutated electric motor with permanent magnet.

- Six sizes - from ED 202 to ED 208.

- High maximum torque, high overload; protection degree IP56/IP66. Each motor is also available with a brake:

- size 2 to 3: brake without airiness; movable with a permanent magnet

- size 4 to 8: brake with minimal airiness; movable with a spring

- size 4 to 7: also available with brake without airiness; resetting the permanent magnet by interrupting with an absolute encode in the inductive design.

- Possible direct mounting of the motor without clutchnja to Stöber's precision drives with minimal airiness.

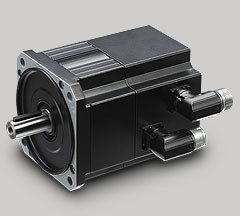

SERVOMOTORS SERIES EK:

- Ideal motor design for axially compressed fittings and short compact construction.

- Brushless, electronically commutated electric motor with permanent magnet.

- Three sizes – from EK501 to EK 803.

- Exceptional circular running at low rotational speeds; high torques; high overload; protection degree IP56/IP66.

- Resetting by interrupting the absolute encode in the inductive design.

- Direct mounting without clutch possible in Stöber precision drives with minimum airiness. Each of the electric motors is also available with a brake, without airiness, with permanent magnet.