Basket

(0)

Search

Equipment

|

Pharmaceutical CIP unitsHygiene is an essential part of the processes of the food processing, cosmetics, pharmaceutical industries as a correct cleaning of all the elements is required. |

|

Manual CIP unitsHygiene is an essential factor of the food processing, cosmetics and pharmaceutical industries. Cleaning must be considered as another stage of the production process |

|

SOLIDMIX Solid-liquid mixing equipmentMixing units provided with blenders are designed to mix solids and liquids with the possibility of total automation and process control. |

|

SIL PIG Product recovery systemThe PIG system is ideal for the recovery of any product remaining in a pipeline in the end of the transfer process. |

|

Valve manifoldManifolds of the INOXPA valves allow to centralize the functions of one or various tanks in a modular way, enhancing the efficiency of the system and control over the process. |

|

PasteuriserThe pasteurisation unit (HTST) is designed for the thermal treatment of milk and dairy products as well as other food products as soft drinks and juices. The process destroys pathogenic microorganisms by heating the product to a moderately high temperature for a brief period. |

|

Table blenders for viscous productsTable mixers for viscous products are used to incorporate solid ingredients into liquid products circulated by a centrifugal and a lobe rotor pump. |

|

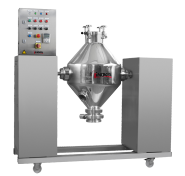

Mixing unit MBCThe double cone blender is used to produce homogeneous solid-solid mixture. |

|

Heat exchanger I7 / I9 / I13 / I26Heat exchangers are extremely versatile: by means of a simple modification in the number of plates, they can be adjusted according to changes in the product flow capacity or changes in the application operating temperature. |

|

Automated table blenderThe table blender is a compact unit, it consists of a centrifugal pump with a venturi system at the suction side and a hopper with a butterfly valve at the upper part to add solid product to the pumped liquid. |

|

Receptrion of raw milk ED-5A tank or trough for the reception of raw milk permits discharge of the milk manually, in milk churns, or by means of cistern trucks. It has a maximum capacity of 5.000 litres/hour. |

|

Maturing / Fermenting unit MFLThe Maturing / Fermenting Unit is a tank which allows milk to be heated and also cooled, with the aim in mind to pasteurize (heat) the product and control its fermentation (cool). The unit can be used to produce yoghurts of different types, fermented milks and sour cream. Additionally this very same equipment forms an integral part of the process to produce butter. |

|

Drainage trolleys for cheese curd CRCUsed to produce fresh cheese, pressed or matured cheese and to stabilize the Ph of curd used to make string-type (“Pasta Filata”) cheese. |